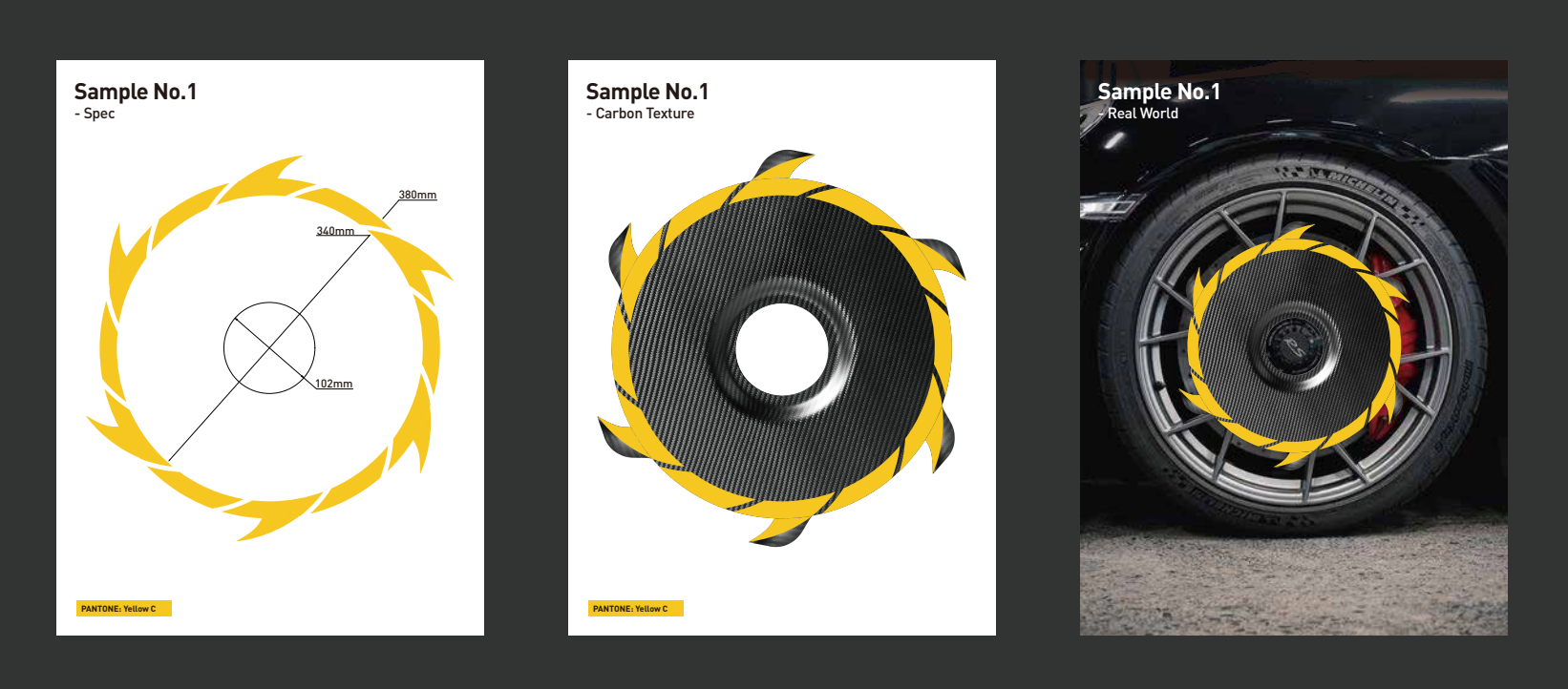

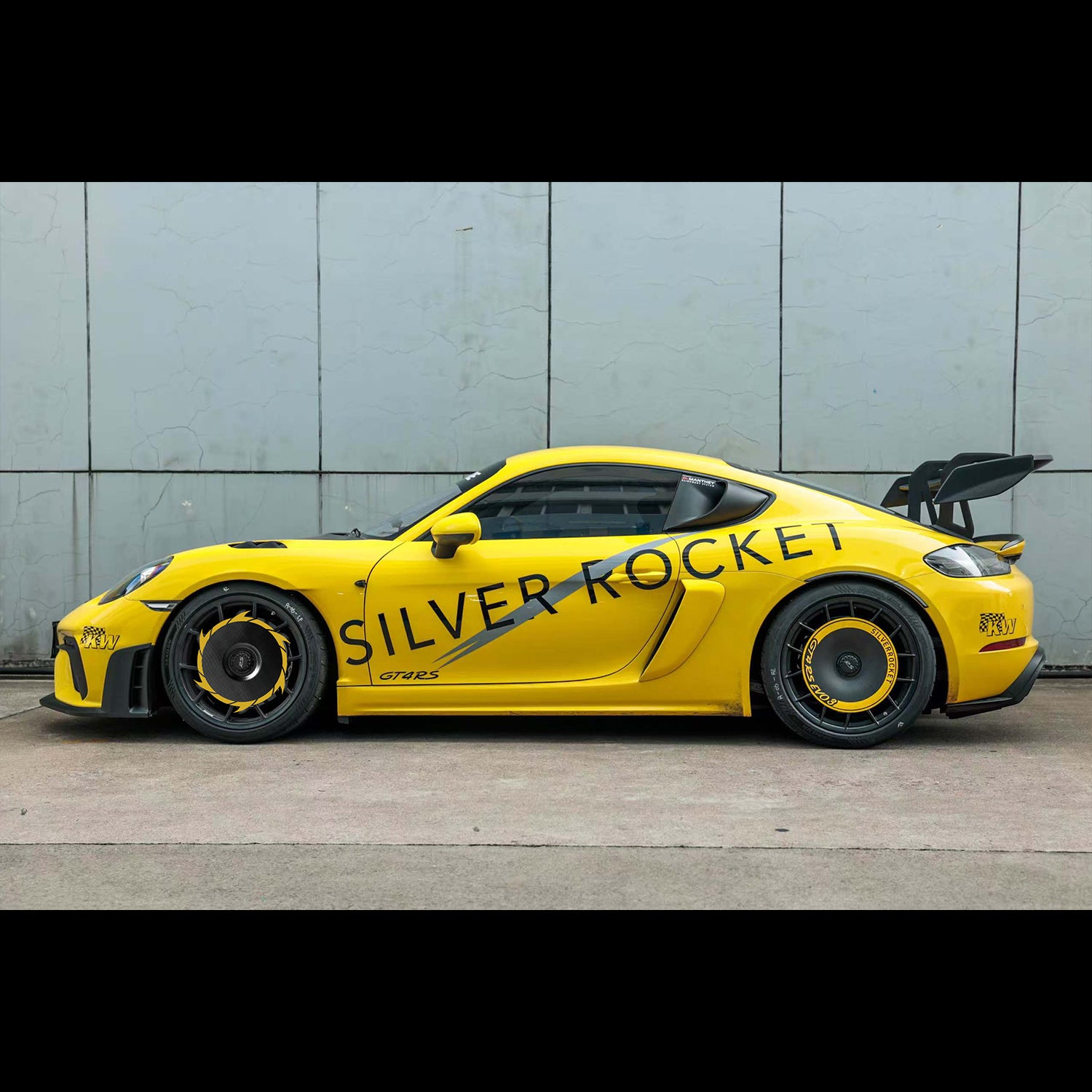

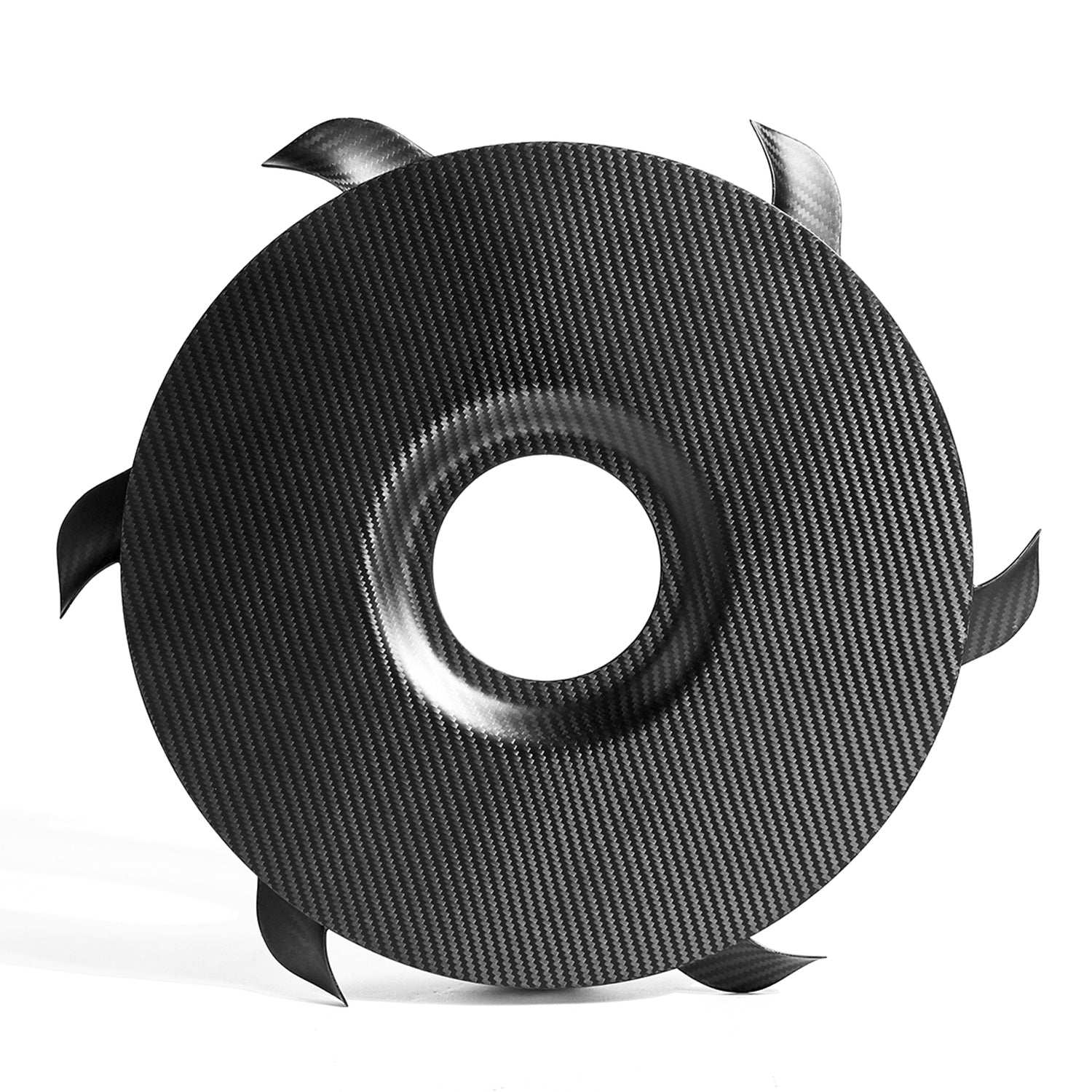

SR DRY CARBON FIBER TURBOFAN AERODISC PRO (for Aluminum FRONT Rims) [PORSCHE 718 GT4 RS]

Highlights:

- Iconic Porsche Le Mans-winning race car design integrated into a modern GT.

- Constructed from dry carbon fiber with race-ready, heat-resistant coating.

- Improved brake system cooling for enhanced performance.

- Increase Drag-Free Downforce on Front Axle.

- Increases top speed on the track, optimizing lap times.

- Aerodisc Pro Livery Free Design Template download here

Application:

-

Only Fits PORSCHE GT4 RS OEM Aluminum Rims

Kon pick-up beschikbaarheid niet laden

PORSCHE HISTORY OF THE TURBOFAN AERODISC

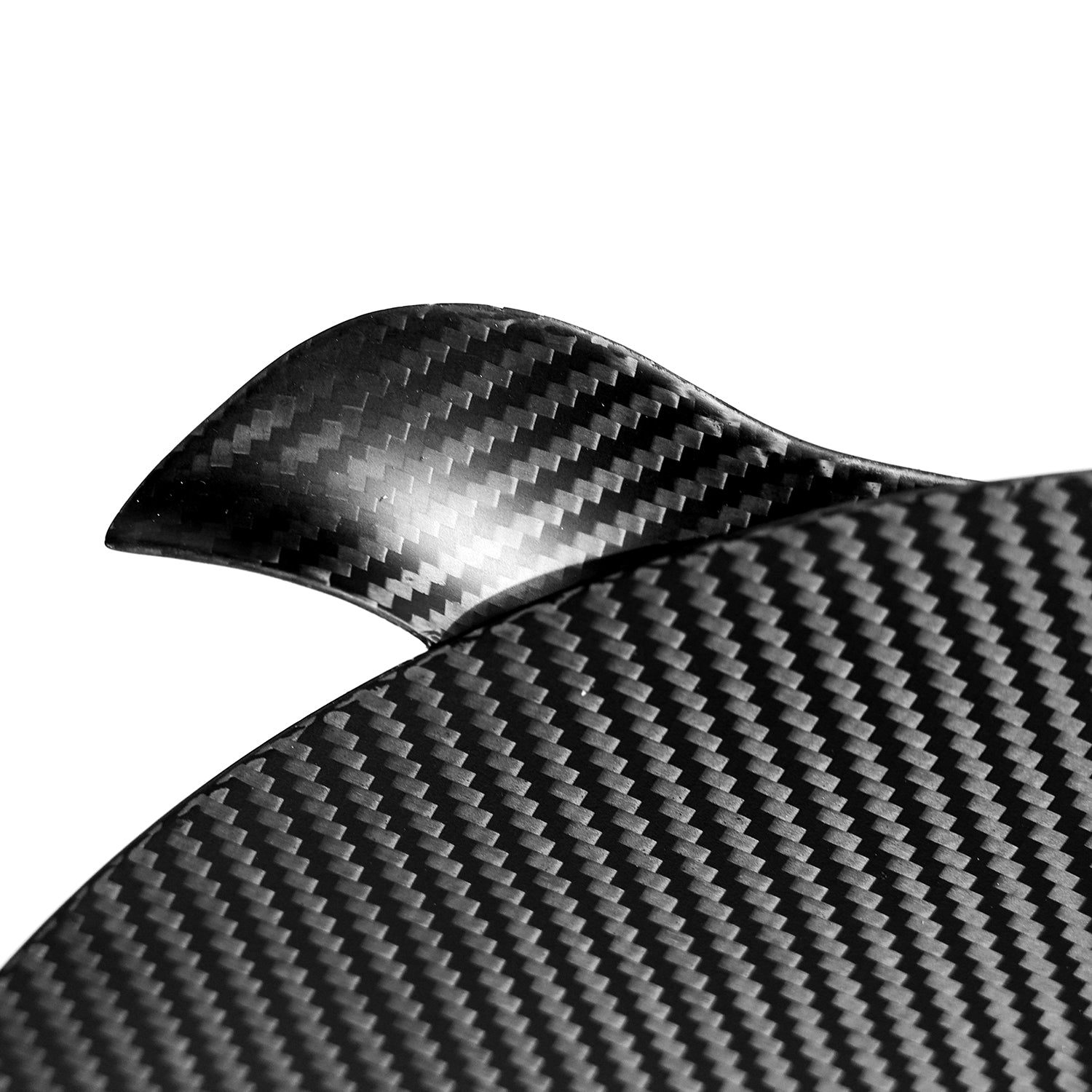

Four decades ago, Porsche introduced a significant aerodynamic innovation known as the turbofan aerodisc, or wheel fan, which remains a subject of intrigue and misunderstanding. This technology first appeared on the Porsche 917/30, a vehicle that dominated the 1973 Can-Am racing series. Widely regarded as the most powerful road racing car of its era, the 917/30 surpassed its predecessor, the 917/10, in speed, size, and weight. During initial testing at Weissach, the 917/30 generated brake temperatures exceeding 700°C (1,290°F), consuming 2.5 inches of brake material in under 300 miles.

Confronted with brake temperatures surpassing the boiling point of contemporary brake fluid, Porsche engineers faced the challenge of managing extreme heat, particularly with the car's wide wheels—15 inches at the front and 19 inches at the rear. Their solution was a set of meticulously crafted, 20-fin wheel fans, or turbofan aerodiscs. The design was straightforward yet effective: radial blades, affixed to the wheel’s outer face, rotated with the wheel to strike and compress air. This action leveraged centrifugal force to expel hot air from the brake system, enhancing cooling efficiency. As long as the wheels spun at sufficient speed, these simple air pumps continuously evacuated superheated air, mitigating the risk of brake failure and improving overall performance.

These devices are no longer utilized in contemporary racing primarily due to regulatory prohibitions enacted by governing bodies. They were classified as movable aerodynamic devices, which violated rules intended to maintain fairness and safety by restricting components that actively alter airflow during motion. Such bans were implemented across various series, including those under the Fédération Internationale de l'Automobile (FIA) and other motorsport organizations, as the turbofans provided an unintended performance advantage through dynamic air evacuation and potential downforce generation.

PORSCHE MODERN PLAYS OF THE AERODISC TECHNOLOGY

Although turbofan aerodisc technology is prohibited in sanctioned racing series due to regulations classifying it as a movable aerodynamic device, Porsche has strategically implemented this innovation in its non-homologated special race cars and official performance kits for GT cars. The technology significantly enhances track performance by improving brake cooling and aerodynamic efficiency, thereby optimizing vehicle handling and speed.

SilverRocket TURBOFAN AERODISC PRO

NEW TECH: AI-DESIGNED HIGH-EFFICIENCY TURBOFAN BLADES

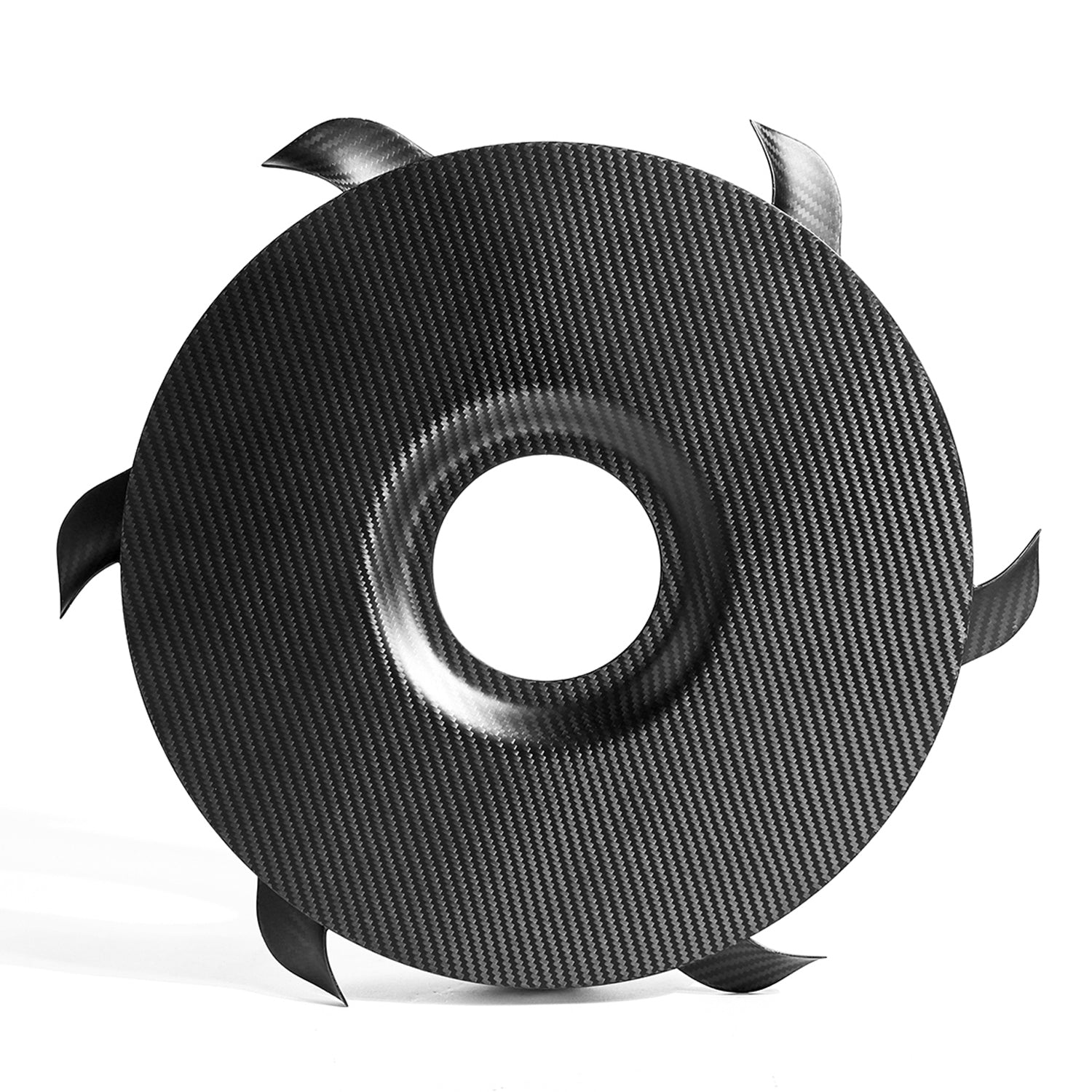

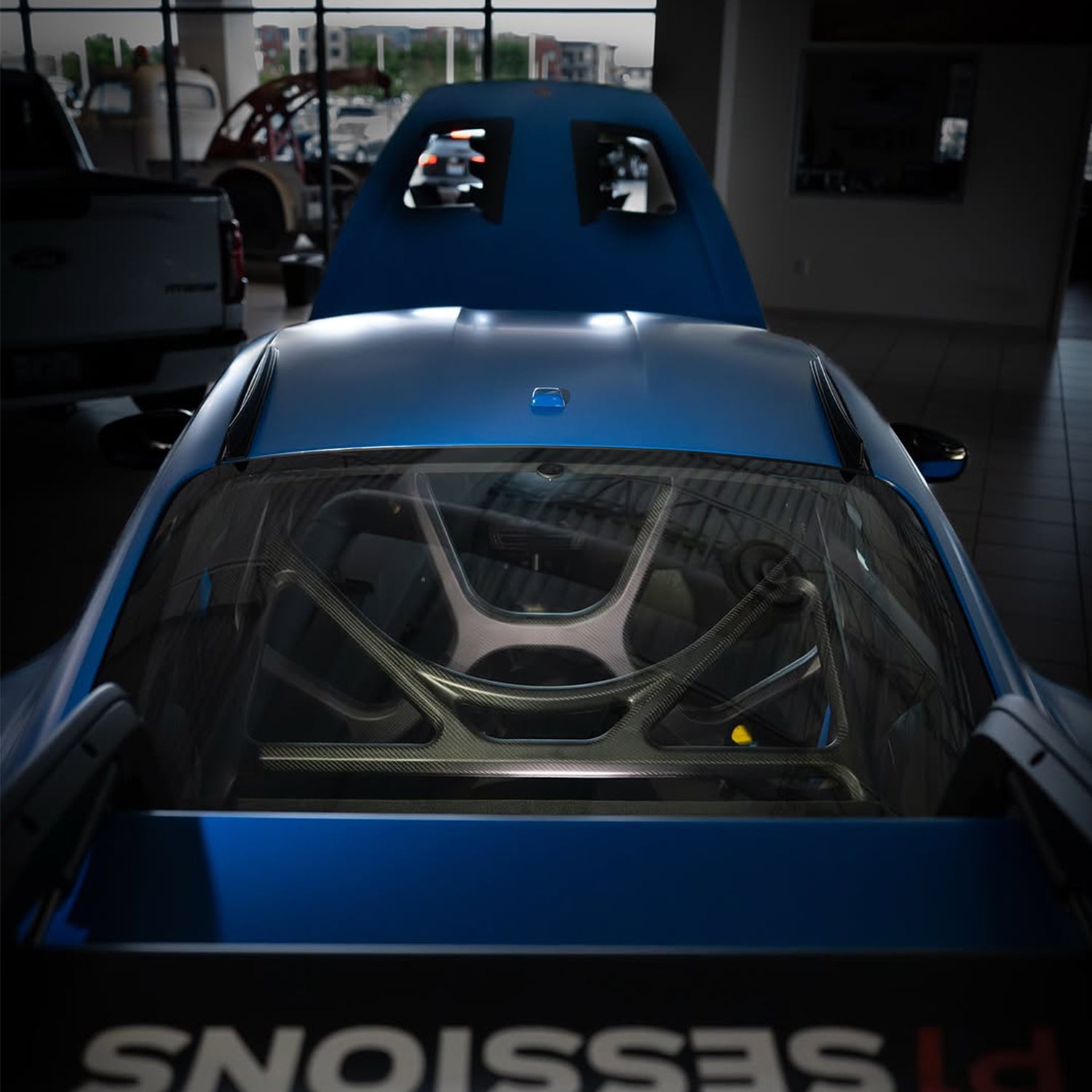

Utilizing state-of-the-art AI-integrated Computational Fluid Dynamics (CFD) software, SilverRocket engineers designed cutting-edge carbon fiber turbofan blades optimized for superior airflow efficiency and minimal weight.

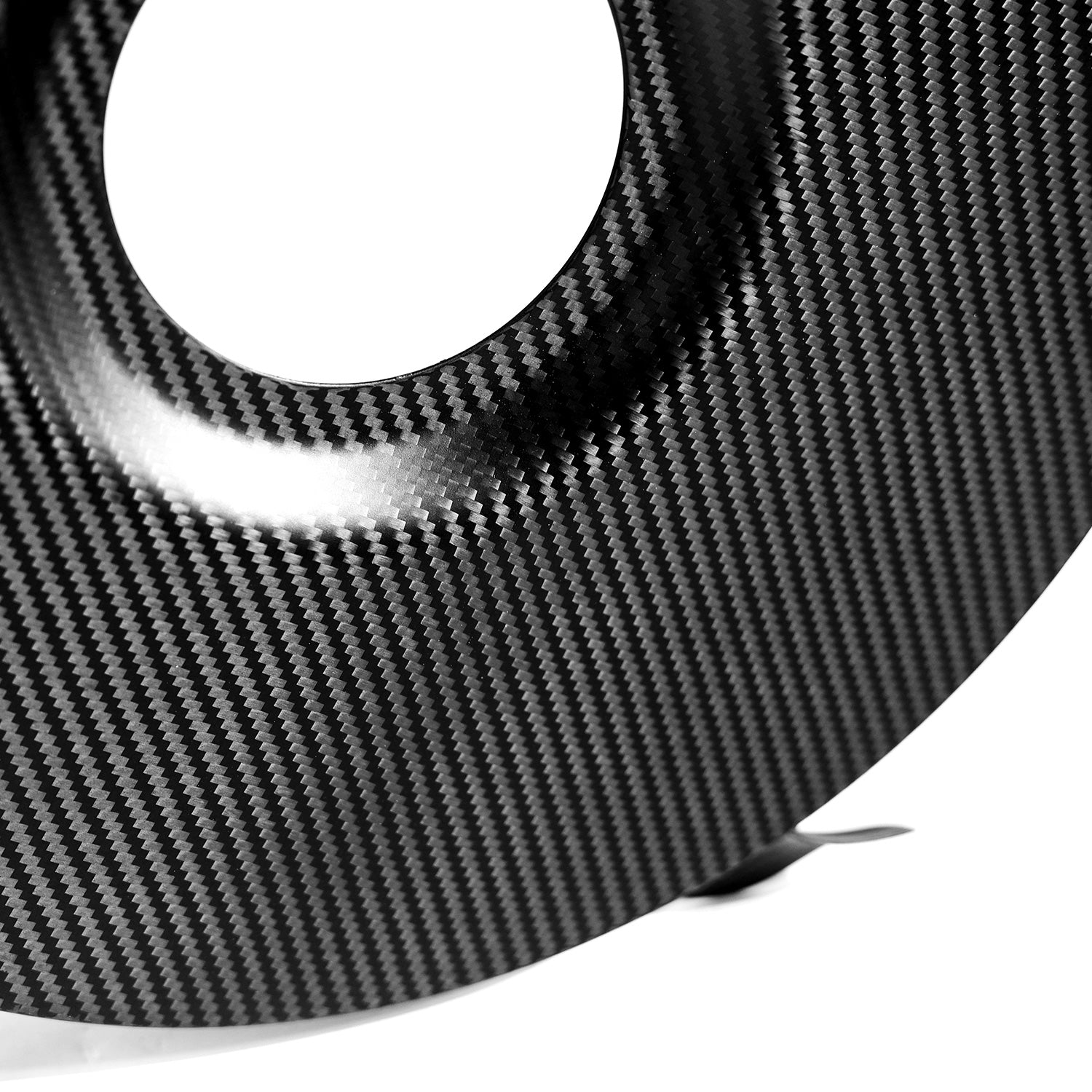

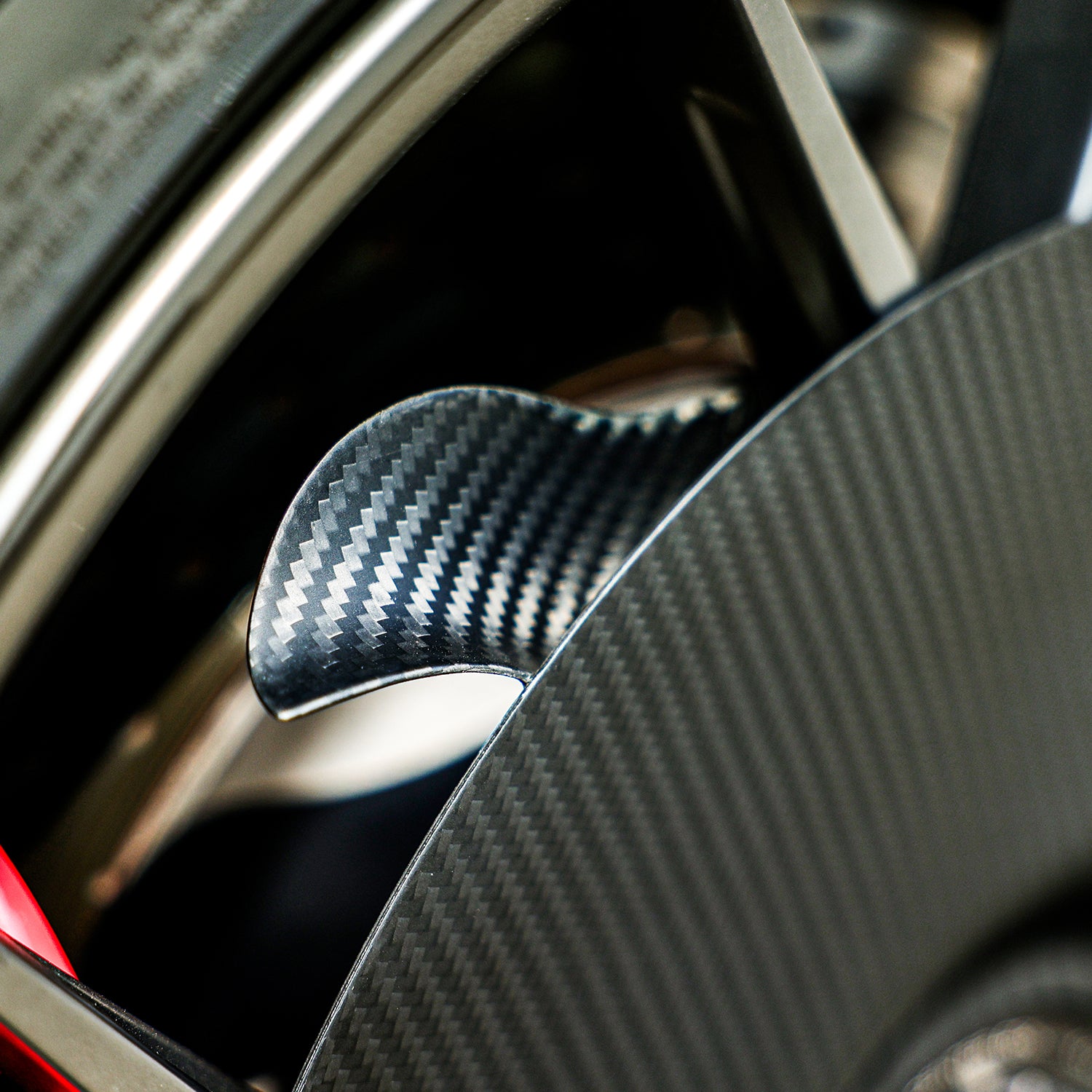

NEW TECH: CARBON FIBER WITH R-HR HEAT RESISTANT COATING

Traditional turbofan rims, typically constructed from aluminum to withstand extreme heat, are suboptimal for maximizing weight reduction. In contrast, the SilverRocket Turbofan AeroDisc Pro utilizes aerospace-grade carbon fiber, delivering superior strength and significantly reduced weight. The innovative SilverRocket RaceReady Heat-Resistant (R-HR) Coating, applied at a 0.5mm thickness across the entire rear surface, ensures exceptional heat resistance, protecting the carbon fiber structure and enabling outstanding durability and performance in high-temperature racing conditions.

RIGOROUSLY TESTED ON RENOWNED F1 TRACKS

To assess the real track performance impacts of the Aerodisc Pro, SilveRocket conducts rigorous testing on racetracks, consistent with its established evaluation process.

BENEFIT 1: ENHANCED BRAKE SYSTEM COOLING

After 30 minutes of intense track driving by a professional driver on a day with ambient temperatures of 40°C (104°F), the left-side wheels equipped with SilverRocket AeroDisc Pro covers demonstrate superior thermal performance compared to the right-side wheels with standard OEM rims. The AeroDisc Pro reduces peak brake disc temperatures from 585°C (1085°F) to 493°C (919°F), enhancing brake system efficiency and durability under extreme racing conditions.

BENEFIT 2: INCREASE DRAG-FREE DOWNFORCE ON FRONT AXLE

The Porsche 718 GT4 RS, compared to the 718 GT4, incorporates fender louvers and arch cuts to extract high-pressure air from the wheel arches, thereby increasing downforce on the front axle.

Similarly, the SR Turbofan Aerodisc Pro enhances front axle downforce by accelerating the extraction of high-pressure air from the wheel arches.

Track testing demonstrates that the additional front axle downforce generated by the SR Turbofan Aerodisc Pro is equivalent to that provided by SR Clubsport dive planes. Notably, the downforce produced by the Turbofan Aerodisc Pro incurs a lower drag penalty compared to dive planes.

BENEFIT 3: MINIMIZING DRAG TO ENHANCE TOP SPEED

The SilverRocket AeroDisc Pro optimizes front wheel airflow, reducing aerodynamic drag.

Track Testing Result shows that, Combined with the rear AeroDisc, SR AeroDisc Pro increases the GT4RS's top speed by 14 km/h (8.7 mph), from 268 km/h (166.5 mph) to 282 km/h (175.2 mph), on the Shanghai F1 Circuit.

A blank canvas for your imagination

While SilverRocket engineers excel at creating solid, track-tested products, we recognize that artistry is not our forte. Therefore, we leave the AeroDisc's front surface blank, inviting you or your favorite designer to unleash your creativity on its design.

To simplify the design process, we created this Design Template: